UIC scientists awarded NASA grant for in-space manufacturing research center

UIC will launch a NASA research center for in-space manufacturing, specializing in in-space recycling and using available materials to support sustainable space exploration, development and civilization.

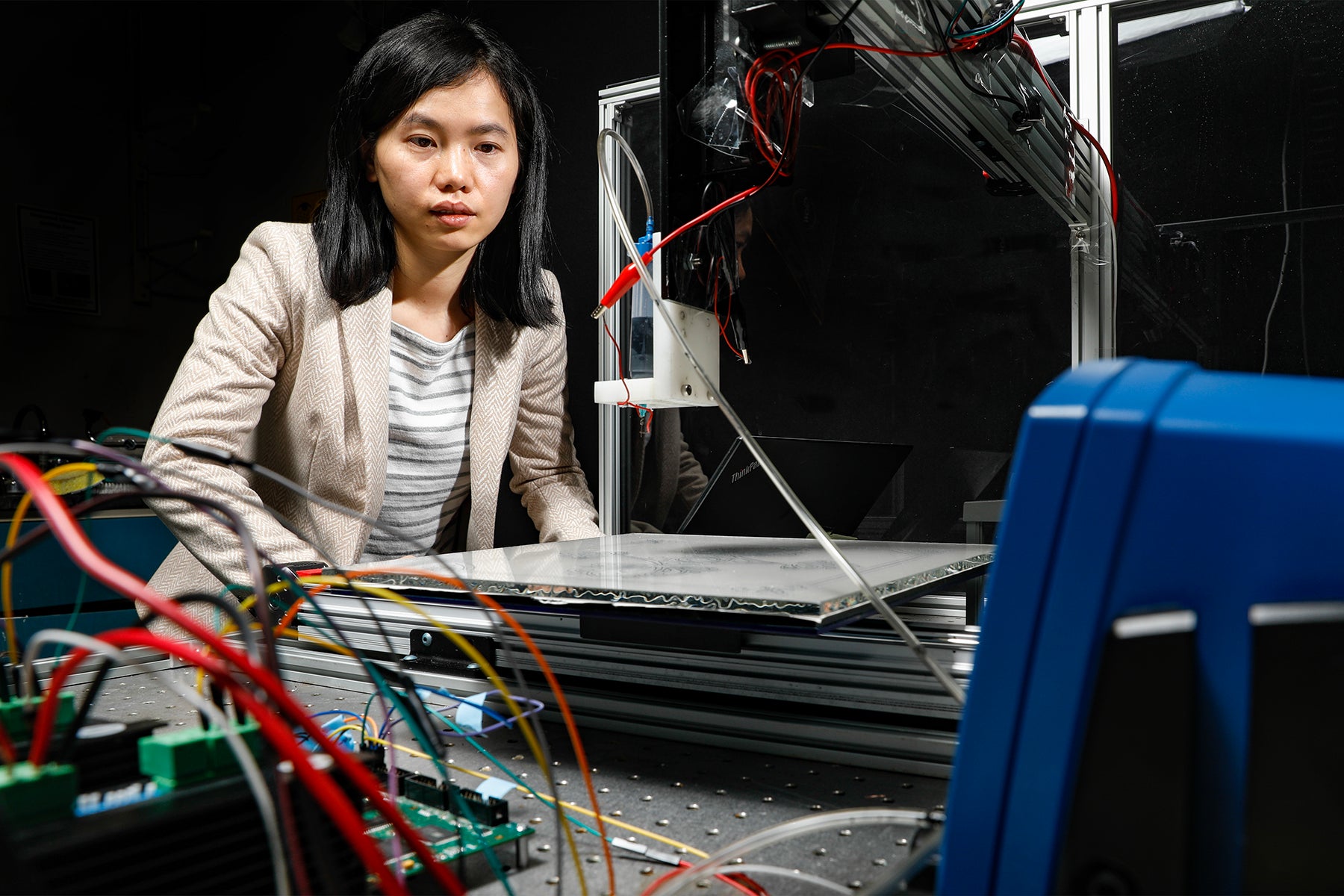

Yayue Pan, associate professor of mechanical and industrial engineering at UIC, has been awarded more than $4.6 million to open the Center for In-Space Manufacturing: Recycling and Regolith Processing at UIC. Joining Pan in the research is professor Jida Huang and professor Lin Li, both working in mechanical and industrial engineering at UIC, and professor Didem Ozevin of civil, materials and environmental engineering at UIC.

The grant was awarded under NASA’s Minority University Research and Education Project Institutional Research Opportunity. The program is focused on helping institutions raise their technological bar and enhance their capabilities and infrastructure to become more competitive in research.

“A major challenge in space exploration is the limited availability of resources,” Pan said. “Through this NASA MIRO Center, we aim to address this limitation by developing advanced manufacturing technologies to enable the recycling of waste materials in space and the processing of planetary regolith.”

Regolith is a blanket of loose deposits covering solid rock. It includes dust, broken rocks and related materials that can be found on Earth’s moon, Mars, some asteroids and other planets and moons.

“In addition to establishing the center, this multi-million project aims to enhance and sustain UIC’s research and education capability in NASA-related areas and promote the inclusion of underrepresented and low-income UIC students,” Pan said. “The center will offer research assistantships for UIC students and internships at NASA Marshall Space Flight Center in Huntsville, Alabama.”

Pan focuses on developing advanced manufacturing technologies. Her research addresses key challenges in additive manufacturing, including limited resolution, inferior material property and restricted material options. Her work aims to transform additive manufacturing into multimaterial and multiscale advanced manufacturing technologies that can produce objects with spatially varying material compositions, intricate multiscale features and programmable material intelligence.

“Our team, with its combined expertise, will build on proven in-space manufacturing technologies endorsed by NASA, and pioneer new techniques and knowledge to expand NASA’s in-space manufacturing capabilities,” Pan said. “The research will explore new composites based on recycled materials and regolith, architected designs for exceptional properties, non-destructive evaluation methods for space-fabricated parts, material-structure-process co-design and sustainability assessments.”

The team is partnering with Northwestern University, Northern Illinois University and the NASA Marshall Space Flight Center. The collaborative effort extends to government, industry and other organizations including DOE Argonne National Laboratory, Chicago mHUB, Contour Crafting Corporation and the American Society for Nondestructive Testing.

In addition to research, the project will organize workshops, develop course materials and increase student participation in NASA-related research fields.