Dentistry-engineering collaboration creates new bone regenerating material

A long-running collaboration between dentistry and engineering researchers at the University of Illinois Chicago has resulted in the development of a thin membrane that can regrow bone, promote healing and protect against infection.

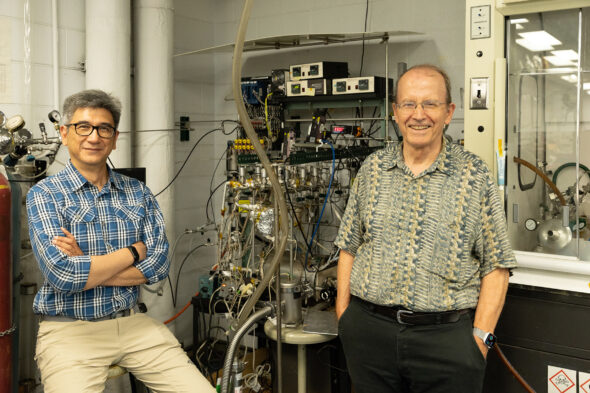

Dr. Cortino Sukotjo and Christos Takoudis led the work and they describe their discovery in a new Bioactive Materials study. The study describes a new method for adding a nanometer-thin layer of magnesium atoms to collagen membranes, which gives new abilities to a common dental tool.

“Magnesium is becoming very popular right now as a way to promote bone healing,” said Sukotjo, professor of restorative dentistry and director of the Pre-Doctoral Implant Clinic. “If we could incorporate magnesium into the collagen membrane, we might be able to accelerate bone healing and induce more blood vessels to grow and supply nutrients to the growing cells.”

When patients receive dental implants, dentists often place a small, thin membrane at the implant site to stimulate the growth of new bone around the implant. This membrane is made of collagen, a protein found throughout the body in the connective tissue between skin, bones and muscles and used for thousands of years for its healing properties.

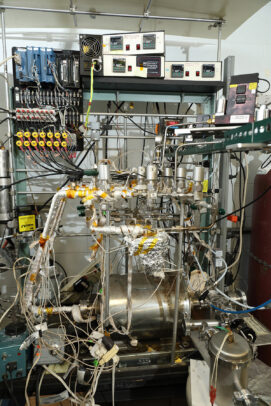

Over a decade ago, Sukotjo and Takoudis, professor of biomedical engineering and chemical engineering at UIC, met at a campus social function and discussed how they could improve upon this simple biomaterial. Takoudis suggested that atomic layer deposition, a technology most commonly used in manufacturing computer chips, could “functionalize” collagen membranes by adding a thin layer of atoms.

The duo first focused on coating the membrane with titanium dioxide and developed new methods of atomic layer deposition that could operate at room temperature so as not to disrupt the collagen. But while the dental implants themselves are often made of titanium, because of the metal’s strength and biocompatibility, magnesium is naturally found in bones and can offer benefits as a supportive micronutrient when the membrane dissolves.

So the researchers adapted their previous method, now coating collagen with magnesium oxide at room temperature. The new magnesium-coated collagen was then tested in cellular and animal models, where it enhanced bone growth and healing and exhibited antimicrobial properties.

The team is now looking at further clinical testing and commercialization of the coated membranes. They’re also testing whether a combination of titanium and magnesium, or perhaps other metals, might be even more effective for bone graft support.

“One of the questions is what element is better: Is it magnesium or is it something else that nobody has tried yet? Our crystal ball is broken, and we cannot guess what’s best. So we are looking at theoretical models of the system, to find the optimal materials to work with,” Takoudis said.

In addition to Sukotjo and Takoudis, UIC co-authors include lead author Soumya Saha, Lin Chen, Abhijit H. Phakatkar, Harshdeep Bhatia and Tolou Shokuhfar. The research was conducted in collaboration with Raphael Cavalcante Costa and Valentim A. R. Barão of the University of Campinas, Brazil, and Mirela Caroline Silva, João Matheus Fonseca-Santos and Leonardo P. Faverani of São Paulo State University in Brazil.

Categories

Health Sciences Colleges, Research, UIC today

Topics

biomaterials, biomedical engineering, dentistry, nanotechnology